Business 1: Innovative Production Technology

Click here→Our developed

Software

↓↓Click here for more information. ↓↓

1.Tradition of Master Craftsmanship Technologies2.Exterior Visual Inspection System using Artificial Intelligence

3.Fault Diagnosis System using Ontology and Artificial Intelligence

4.Education System using Ontology

5.Procurement Proposal for Production Line to be maintained and updated

6.Inspection System integrated with Production Process

7.BI (Business Intelligence)

Supplementary Explanation

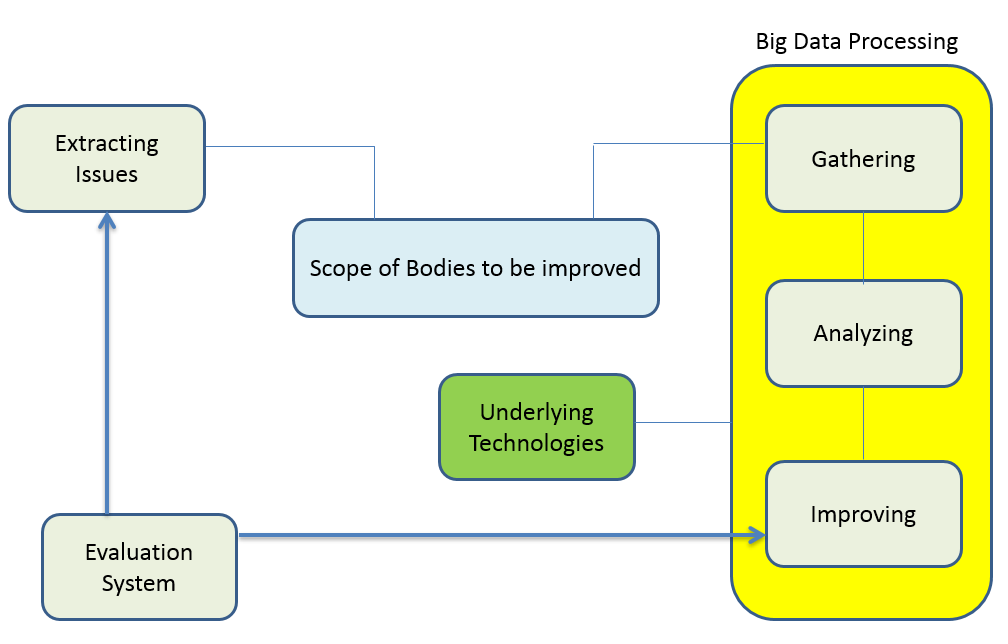

・“Scope of Bodies": This means a scope of target body, for example, a manufacturing line, a plant or a whole company, and our recommended approach is, in principle, a wide range as possible as we can. In a certain case such as logistic issues, we can study this as a supply chain.

・“Extracting Issues”: Some of issues faced by companies would be latent or potential, and some have become apparent or actualizing. Some of the issues are to be set as a future goal. In any case, our policy is that we aim for “all optimizations, not partial optimizations”. For this reason, as mentioned above, the target bodies are widely considered.

・“Underlying Technologies" and "Improvement Measures (improving)": We collect and analyze the related information (through the IOT and other methods as Big Data) and propose improvement measures as outputs of such study. For such purposes, artificial intelligence, data science might be applicable. In addition, visualization would be also useful, and the problems which have been hidden would be visualized into surface to clean out them.

・“Evaluation System”: It is necessary to quantitatively indicate how much improvement has been made and how much cost has been reduced. By establishment of an evaluation system, the return on investment and the recovery of funds are embodied, and the effects of improvement are clarified.